Digital transformation involves the integration of innovative technologies to revolutionize and reshape business operations. It goes beyond the simple implementation or enhancement of existing technology solutions, as it requires a comprehensive reevaluation of all aspects of the business, seeking ways in which technology can enhance the synergy between humans and machines for greater effectiveness and efficiency.

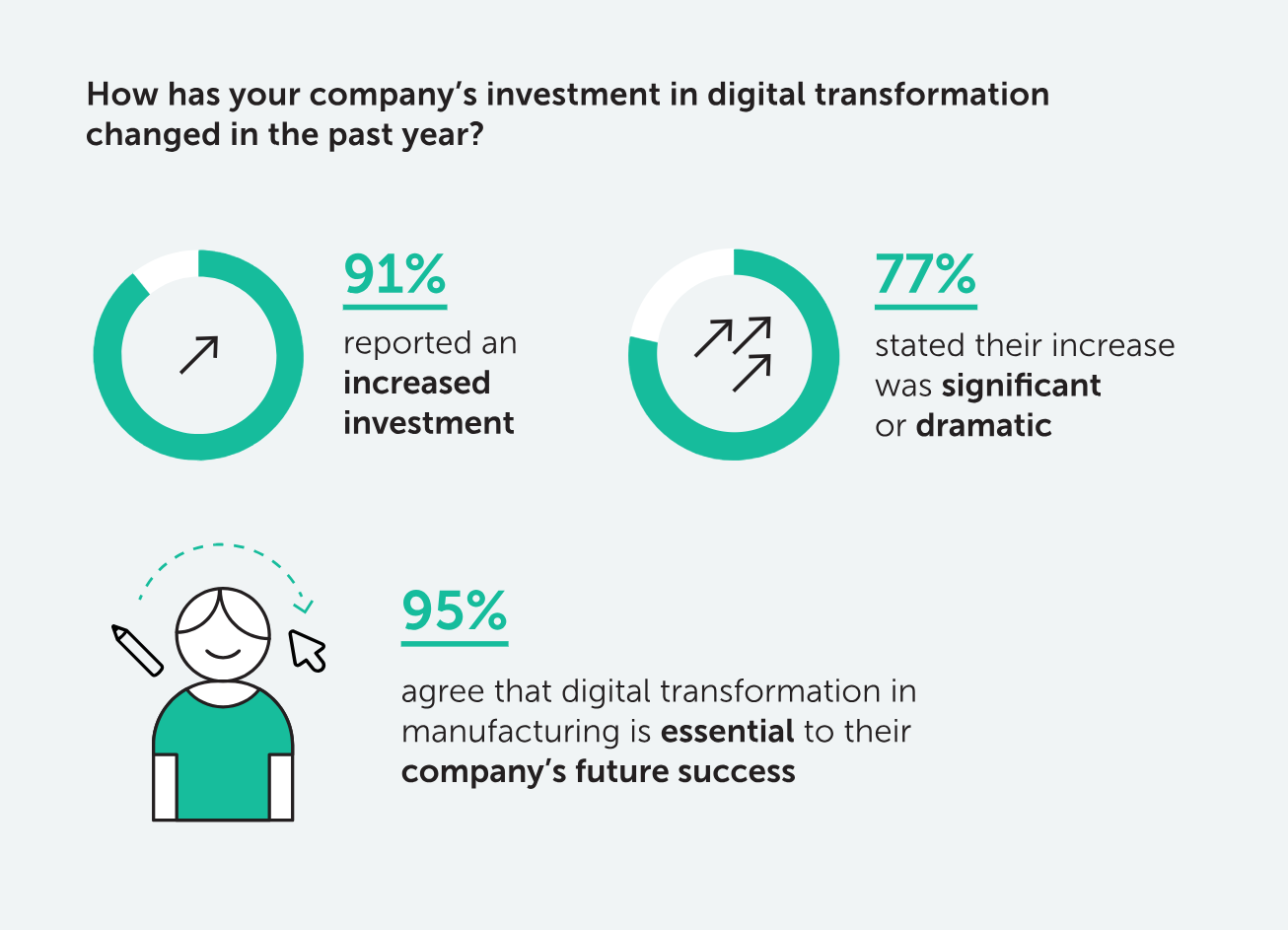

In the year 2021, manufacturers recognized the significance of digital transformation and made substantial investments in technology, acknowledging its indispensable role in achieving success.

However, what exactly constitutes industrial digital transformation, and how does it manifest in practical, real-world scenarios? Refer to this guide for a deeper insight into the essence of digital transformation within industrial enterprises, the advantages and obstacles associated with this process, the steps involved in implementing digital transformation, and explore tangible instances of industrial companies undergoing a profound technological makeover.

What is Industrial Digital Transformation?

Industrial digital transformation marks a pivotal shift in the landscape of industrial operations. It empowers companies to adapt to the ever-changing technological terrain, ensuring their competitiveness in the digital era. These digital transformation tools not only enable individuals to work more intelligently but also liberate human resources from monotonous and routine tasks, affording them the opportunity to focus on their core strengths: interpersonal interactions and creative thinking.

- Internet of Things (IoT)

- eCommerce

- Artificial intelligence (AI)

- Big data analytics

- Cloud computing Automation

Automation Increasingly, modern digital transformation trends blend multiple technologies for comprehensive solutions. For instance, a digital transformation in the industrial sector might leverage a cloud-based B2B eCommerce platform to automate order placement on the customer-facing side and streamline order processing on the backend. This approach allows the buyer to enhance their procurement capabilities, while the seller gains more time for building relationships and nurturing potential business opportunities.

Advantages and Obstacles of Implementing Digital Transformation in the Industrial Sector

The digital transformation of industrial enterprises equips them with digital tools and data-driven insights, facilitating more informed decision-making, enhanced supply chain efficiency, improved product quality, and the creation of personalized customer experiences. While these advantages are substantial, they do not come without accompanying challenges.

Advantages of Digital Transformation in the Industrial Sector

Implementing digital transformation in industrial enterprises yields several advantages, including:

- Enhanced Productivity: Cloud-based computing empowers employees to work more efficiently, enabling remote access to digital tools and software necessary for their tasks. Moreover, the integration of AI and automation reduces the need for manual data entry and some data analysis, enabling human resources to concentrate on high-value activities.

- Heightened Operational Flexibility: IoT technology identifies potential issues before they materialize, allowing for swift adjustments in production to schedule maintenance preemptively, preventing equipment breakdowns. Big data analytics detects emerging trends, enabling companies to respond promptly to market shifts.

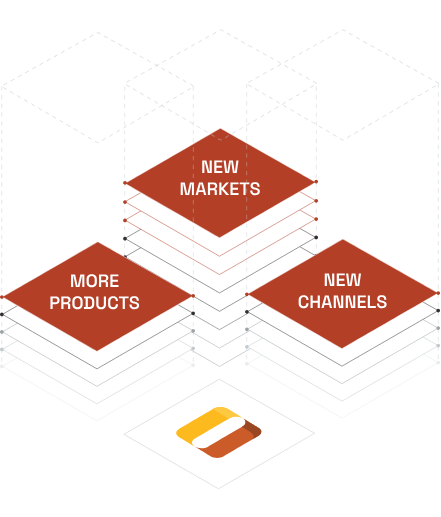

- Innovation in Business Models: Industrial digital transformation, coupled with eCommerce, facilitates the effortless creation of novel business models. Companies can transition from traditional B2B models to embrace B2B2C, DTC (Direct-to-Consumer), or even establish their own online marketplaces. Digital tools enable manufacturers to establish online platforms for distributors and retailers, empowering them to participate in eCommerce initiatives.

Obstacles in the Path of Digital Transformation in the Industrial Sector

Realizing the benefits of digital transformation necessitates surmounting a set of challenges. Here are some obstacles you may encounter along your transformation journey:

- Outdated Technology: Many industrial companies grapple with legacy systems that lack compatibility with emerging technologies. The integration and upgrade of these systems can be intricate and costly, demanding meticulous planning and judicious product selection.

- Data Management and Security: The very digital tools that offer numerous advantages often generate vast volumes of data that require robust security measures. In the face of evolving cyber threats, safeguarding data privacy and security is of paramount importance. Furthermore, once data is collected, effective management is crucial to extract meaningful insights.

- Change Management: Digital transformation brings about substantial alterations in workflows, processes, and at times, even the organizational structure itself. Effectively managing this change, which encompasses securing employee buy-in, addressing resistance, and fostering a digital culture, hinges on strong leadership and proficient change management strategies.

Overcoming these challenges mandates a strategic approach, involving meticulous planning, collaboration with technology partners, effective change management strategies, and a forward-looking vision for digital transformation. Industrial companies must thoroughly evaluate their specific challenges and develop a roadmap that aligns with their business objectives and available resources.

Step-by-Step Guide for Executing Digital Transformation in Industrial Enterprises

Digital transformation in the manufacturing sector not only brings about immediate changes but also positions the company for long-term success. Here are the steps to embark on the journey of continuous transformation:

- Develop a Roadmap: Just like any journey, a digital transformation necessitates a well-structured roadmap aligned with your business objectives. Start by assessing your current digital maturity and existing technology infrastructure. Define where you want to be and the level of maturity you aim to achieve in 3 to 5 years. This process helps identify the gaps that need to be addressed.

- Adopt an MVP Approach: Transformation is an ongoing process. Implement the Minimum Viable Product (MVP) approach, setting achievable goals, testing, launching, gathering feedback, iterating, and repeating the process iteratively. This method minimizes risk and cost while allowing you to validate new technology and processes.

- Establish an Integrated Environment: To maximize the benefits of digital transformation, ensure that your systems and platforms are seamlessly integrated. Eliminate data silos to enable the free flow of information throughout the organization and into the hands of decision-makers. When selecting technology solutions, prioritize integration capabilities, including APIs that facilitate connections. Ensure that ERPs, eCommerce platforms, CRMs, PIMs, and other solutions can share data for task automation.

- Leverage Data and Analytics: Capitalize on the data and analytics generated by your digital transformation efforts. Utilize advanced data analytics to gain insights from sales data, customer behavior, market trends, and demand patterns. Improve the ROI of marketing campaigns, enhance purchasing practices, optimize inventory management, and align production planning accordingly. Make the most of available data through dashboards and analytics. Scale Incrementally: Extend the digital transformation beyond the manufacturing floor and incrementally scale solutions across the entire organization. Include back-office functions in the digital transformation process. Implement customer relationship management (CRM) systems to streamline sales processes, enhance customer data management, and inform targeted marketing and sales strategies. Utilize workflow automation to streamline processes, reduce errors, boost productivity, and free up employees’ time for high-value tasks.

Industrial Digital Transformation Solutions: OroCommerce Case Studies

OroCommerce offers a comprehensive suite of tools that cater to the requirements of various B2B sellers, including industrial, packaging, and construction companies, facilitating their digital transformation through eCommerce.

Even traditionally brick-and-mortar enterprises, like specialty food ingredient and chemical companies, have harnessed the flexibility and robust capabilities of the OroCommerce eCommerce platform to establish a digital presence. These are just a handful of examples of the numerous industrial digital transformations in which OroCommerce plays a pivotal role.

ADDEV Materials

ADDEV Materials, a chemical company specializing in advanced material transformation processes, which include converting films, adhesive solutions, and customized packaging solutions for the aerospace, defense, transportation, and construction sectors, embarked on a digital transformation journey with the aim of enhancing customer value, strengthening relationships, and reducing order processing costs. Leveraging OroCommerce, they established a unified backend to manage three distinct websites. This setup introduced features like request for quotes and quick order forms, enabling customers and leads to receive swift responses. The incorporation of marketing automation tools improved upselling and cross-selling efforts. Today, 16% of their online business originates from new customers, contributing to the growth of a larger and more robust customer base. This transformation not only provides customers with a seamless experience but also equips employees with enhanced data analytics and automated workflows through integrated ERP and payment systems.

Azelis

Azelis provides specialty food ingredients and chemicals to customers worldwide.

The goal of the digital transformation was to provide their increasingly younger and more tech-savvy customers with the B2C-like experience they demanded in this traditionally offline industry. With OroCommerce, they found a solution that could service their global presence through robust localization features right out of the box. Customers now enjoy a full self-service shopping experience while maintaining the option to talk to a sales representative at any time.

Conclusion

Industrial digital transformation leverages digital technologies to streamline processes, boost efficiency, and foster innovation. Employing tools such as the Internet of Things (IoT), artificial intelligence (AI), cloud computing, process automation, and eCommerce, operations harness the full potential of human and technological resources. For organizations initiating a digital transformation, it’s imperative to begin with a well-defined roadmap and adopt the Minimum Viable Product (MVP) approach to establish an integrated ecosystem. Furthermore, they should harness the data and analytics they accumulate and progressively expand their achievements across the entire company.

Contact us via contact@ekino.vn to discover more about OroCommerce’s capabilities.

Note: Content for this post was originally posted on Oroinc.com

Original content page: https://oroinc.com/b2b-ecommerce/blog/industrial-digital-transformation/